Labels

Blog Archive

- 2013 (1)

-

2012

(67)

-

October(34)

- October the 31st

- October the 30th

- October the 29th

- October the 28th

- October the 27th

- October the 26th

- October the 25th

- October the 24th

- October the 23rd

- October the 22nd

- October the 21st

- October the 20th

- October the 19th

- October the 18th

- October the 17th

- Taking Turbulence detection to the next level

- October the 16th

- October the 15th

- October the 14th

- October the 12th

- October the 13th

- October the 10th

- October the 9th

- October the 8th

- October the 7th

- October the 6th

- October the 5th

- October the 4th

- October the 3rd

- Additive manufacturing

- October the 2nd

- Quality assurance for Composite materials

- Goodrich Corp’s GA64OC-15A shortwave infrared came...

- October the 1st

- September(31)

- August(2)

-

October(34)

Additive manufacturing

When you refer to disruptive technology-a type of technology that disrupts the normal day to day operations, meaning it is unique in such a way that manufacturers need to get used to it in a major way-though the package includes advantages in expenses, time and efficiency. Many people, just like the Director of GE Aviation does, think of additive manufacturing as some kind of disruptive technology.

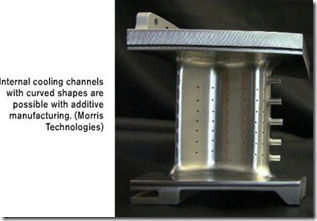

Power-bed additive technology builds up parts by stratification and bonding (using concentrated heat sources like electron beams or lasers) of layers on top of each other, forming cross sections of the part in 20-80 micron thicknesses. The outcome of the process can be very complex parts that cannot be produced using the commonplace methods. It can also combine and put together items from traditional manufacturing processes to form intricate mechanisms. Most of the hackneyed manufacturing processes build components with multiple steps or need multiple parts brazed together while additive manufacturing allows one to combine these into one big step. This means the complex parts can be optimized for weight and strength to serve different critical applications.

Additive manufacturing, though still an immature field as of today, shows signs of exponential growth. This growth seems to be going hand in hand with propping technologies like software and computing. Industrial players also expect an increase in the size of parts that can be manufactured.

About Me

- AICHA EUGENE

- Aicha Eugene is a Mechatronics Engineering student at JKUAT in Kenya. He is also a student member of the SAE.

0 comments:

Post a Comment