Labels

Blog Archive

- 2013 (1)

-

2012

(67)

- October(34)

-

September(31)

- September the 30th

- What about internet during our flight?

- September the 29th

- Something is missing….Bird strike kills all!

- September the 28th

- September the 27th

- September the 26th

- September the 25th

- September the 24th

- September the 23rd

- September the 22nd

- September the 21st

- September the 20th

- September the 19th

- September the 18th

- September the 17th

- September the 16th

- September the 15th

- September the 14th

- Top five reasons why Aviation is my way to go

- Effect of wind farms on radar signals

- September the 13th

- The composite fear factor

- Antonov AN-28 crashes at Palana, Russia on 12th Se...

- September the 12th

- Welcome to Avitech Reader!

- September the 11th

- The Airbus Beluga

- B-1 Bomber Targeting pod software for precision

- What is the Airframe

- Diesel engines in Aircraft-what do you think?

- August(2)

What is the Airframe

By airframe when it relates to an aircraft we are referring to the mechanical structure of the plane. This includes the fuselage, wings, fin or vertical stabilizer(form the empennage), ailerons and the landing gear. It does not include the electronic system(avionics) or the engines. In aerospace engineering and research, its important to note that the airframe design is a vital elements and combines aerodynamics, manufacturing techniques and material science to achieve its designated purpose or objective. For example, the wings has a certain aerodynamic shape to achieve lift while the landing gear is to be made using specific shock absorbing material and at the same time possess the toughness to withstand impact. The whole airframe has to be robust enough to withstand the stresses it goes through and also balance the safety, reliability and economics. Airframe structures is not something that just came out recently, it can be clearly seen even when you look at the aircraft built by Orville and Wilbur Wright. It has only been advanced and developed over the years to couple its development with technology. I remember during our Aviation Technology classes at Maseno School we learnt about the warren truss structure, the monocoque and the semi-monoloque structures and differentiated between them in details.

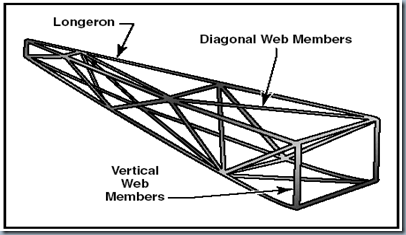

The fuselage is also what we know as the main body of the aircraft and provides room for controls, our payload, passengers and the crew.It also provides attachment for wings, the landing gear, the empennage and the powerplant. In the early days, the fuselage was made by welding, riveting or bolting together aluminium tubes and steel rods to form a tapering box like structure whose strength mainly dependent on the weld joints and the strength of the aluminium and steel. The longitudinal members called longerons and the vertical web members had to bear the aerodynamic stresses depending on the direction in which the stresses will be acting. Later on as technology advanced, designs were developed to enclose the truss with a covering, first was cloth which paved way to the light metal sheets like aluminium that ended up bearing most of the flight loads in the monocoque and semi-monocoque construction. The stressed skin provides enough force but if dented or deformed then it can easily give in.It just works like an aluminium can, if it has no dent or deformation, it can be very strong but once it has a hole then it would give in to a substantial amount of force applied.

The true monocoque structure consists of bulkheads, formers and the skin. The formers and bulkheads give shape to the structure. Here, in the monocoque construction , the skin just has to be strong enough to bare all the stresses hence the main challenge is to make it strong without adding its weight so much-a hard compromise. That is why we have the semi-monocoque structure that that has bracing members on which the skin is attached and these bracing members take some of the stresses and its not only left for the skin. This bracing substructure is made up of stringers, variety of sizes of bulkheads and formers to support and ease forces on the stressed skin.

About Me

- AICHA EUGENE

- Aicha Eugene is a Mechatronics Engineering student at JKUAT in Kenya. He is also a student member of the SAE.

0 comments:

Post a Comment